This is an ongoing project car owned by Ross Farnham of Racetech Inc. Look for updates and more pictures as they become available.

This 240SX was selected to act as a daily driven test bed for SDS products. Straightline performance of the stock vehicle can only be described as inadequate. Vericom testing revealed stunning acceleration with 0-60 taking 9.84 seconds and the 1/4 mile at 17.16@85 mph. This at 3500 feet and 60 degrees F ambient air temp.

The goal of this project was to have lots of low end torque with a super wide power band, good fuel economy, low noise level and factory cruise and A/C operation intact. I wanted a good highway cruising vehicle. Stealth is always important on our cars so there are no flashy graphics, chrome or 5 inch exhaust pipes to give away what lurks underneath. Sheer speed is not the aim of this car but rather quick, reliable performance at under 10 psi boost.

Turbocharging was obviously a must. I drove the vehicle stock for 2 weeks, waiting for all of the bits to arrive. Nissan should be ashamed of the stock driveability that their ECCS delivered. The idle speed control with 3 different control systems was atrocious. Other faults with closed loop being engaged too early in the warmup cycle were also evident. The engine felt very weak below 3500 then not bad to about 5000, then very stifled above that, probably by the restrictive intake and exhaust systems.

Anyway, the most fun was probably removing all of the factory crap and there is LOTS of it. A multitude of what I call fridgistat valves, hoses, more hoses, extraneous wiring, EGR crap, the ugly airflow meter and the 71 lb exhaust system. I could actually see the engine after this.

Intake

I started with the intake. The stock injectors were removed because they are too small for turbo use at 260cc/min. They were replaced with 470cc Racetech injectors by machining aluminum adapters and spacers to adapt to the larger O-ring style. The EGR port was plugged off as were many of the vacuum ports and idle speed control valves. A GM water temp sensor was mounted in the bottom of the water outlet runner. The ridiculous supplementary air valves and actuator were removed also from the intake manifold for better airflow.

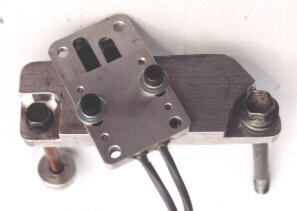

Hall Sensor

The Hall sensor for the F system required a mount to be built off of the timing cover on the lower left. This was machined out of � inch T6 plate. The crank pulley was removed and fitted with the 3 magnets required to trigger the F system.

Header

A custom header was fabricated out of schedule 40 weld els in 1.25 inch ID. The turbo flange was angled to allow for easier exhaust outlet plumbing, air filter placement, brake master clearance and A/C hose clearance. Primaries 1 and 4 and 2 and 3 were grouped together for maximum pulse energy and lower backpressure. Everything was then TIG welded.

Turbocharger

This was purchased from Turbonetics. It is a T4/T3 hybrid and uses an H-3 compressor with stage 3 turbine wheel in a .63 housing with an integral wastegate and dual port actuator. This was chosen for the most efficient compressor match for low discharge temperatures and low mass on the turbine end with reasonably low backpressure at high boost. Response and flexibility were the aims here. The H-3 also offers decent breathing off boost with a large inlet area.

Exhaust system

This was made using 2.5 inch mild steel tubing and mandrel bends. With a T3 turbine, 2.5 inch is all that is required. This made plumbing and ground clearance problems minimal. A Dynomax Super Turbo muffler was fitted for low noise.

Intercooler

Our standard Spearco core 2-161 was used for low cost and good performance. This is 7.9 x 12.88 x 3.5 inches and fits nicely ahead of the rad. At 250 hp, the pressure drop should be around .8 psi and the efficiency at 60 mph should be in excess of 90%. 2.25 inch mandrel bent tubing is used for plumbing the intercooler.

Engine Management System

I fitted our standard EM-2F, direct fire system to my car. This freed up a lot of space in the left front corner of the engine compartment by eliminating the airflow meter and air filter. This also enabled the distributor to be removed which allows a convenient place for the turbo oil to be drained back without removing the oil pan.

The stock ECU was removed from the right kick panel along with hundreds of feet of stock wiring. The EM-2 was placed in the same spot. The cruise control computer is separate so everything still works there. The A/C control was more difficult. We had to add a special relay to control it and are still formulating some new software to control engine idle speed.

Boost Control

I fitted our standard DBC to control the integral type actuator.

Wheels and Tires

I installed 15 X 7 ASA wheels and Yokohama A520 205 55 15 tires for some decent grip. These lowered the car a bit and look great. I chose not to lower the car via springs because the car will be winter driven so I need some ground clearance and did not want a bone jarring ride at -30. I'll fit some Blizzaks onto the stock rims for winter use.

Driving It

The engine started immediately and idled well within 5 minutes with slight adjustments.

The car drove quite well with standard settings. About 30 minutes were spent on initial programming out on a deserted stretch of road. Torque at only 3.5 psi was astounding compared to stock. Effortless cruising and hill climbing were demonstrated in 5th gear. This engine tolerates extremely lean mixtures under cruising and low boost operation with AFRs around 19 to 1 at cruise. Fuel economy is about the same as stock - around 28 mpg combined hiway and city. This engine is extremely flexible with boost starting at 2000 rpm and tons of torque available at 3000 and up. Passing exposure in 5th is halved over stock even at low boost. The engine has more torque than stock even from 1500 rpm. It pulls hard to redline and I am just experimenting turning up the boost at this point with the new clutch.

The stock clutch was found to slip in 5th at only 5 psi so an ACT performance unit was fitted. This clutch is stiff but will never slip. The stock rubber driveshaft coupling is annoying with the extra torque available and makes getting the car off the line smoothly a bit difficult even in stock trim. I dislike this aspect of the car the most and it may have to go.

I have spiked the 92 octane pump gas with a gallon of M-85 to reduce the ignition retard under boost and pick up the power. I use this strategy on my turbo Corolla as well with excellent results

Performance Testing with Vericom

With the ACT clutch installed and EM-2 programming mostly complete, I installed the Vericom for some testing. Tests were run at 3600 feet and 73 degrees F with only 7.5 psi boost.

0-60 mph 5.88 seconds

1/4 mile [email protected] mph

Braking 60-0 118 feet/ 1.21 G peak

Calculated HP 284

These figures are most impressive. Note that this is a bone stock ,12 valve engine internally with about 90,000 miles on it. No porting, no cam. These are 205 street tires and not slicks. The suspension is all factory stock. There is no limited slip. The car is at stock weight with air conditioning, sunroof, power locks and windows intact and note the altitude and boost pressure.

Anyone who discounts the 240 engine as a crude truck motor without performance potential should look at these figures. It is hard to beat cubic inches when it comes to torque. At only 7.5 psi, the stock hp has been DOUBLED. Think of what a fresh, 16 valve would do with porting, cams and 15 psi. Probably 500 + hp.

One of the first victims of the 240 was a 4.6 liter DOHC Mustang which I liquidated at only 3.5 psi. It was no contest at all.

Mileage is pegged at 31-33 mpg (Imperial) on the hiway at speeds from 75-90 mph.

Injector duty cycle reaches 85% which when worked back at a SFC of .55 lbs/hp/hr. Indicates 290 hp which is very close to the Vericom.